Zhengda Valve

One-Stop Supplier for Rubber Joints, Bellows, and Waterproof Casings

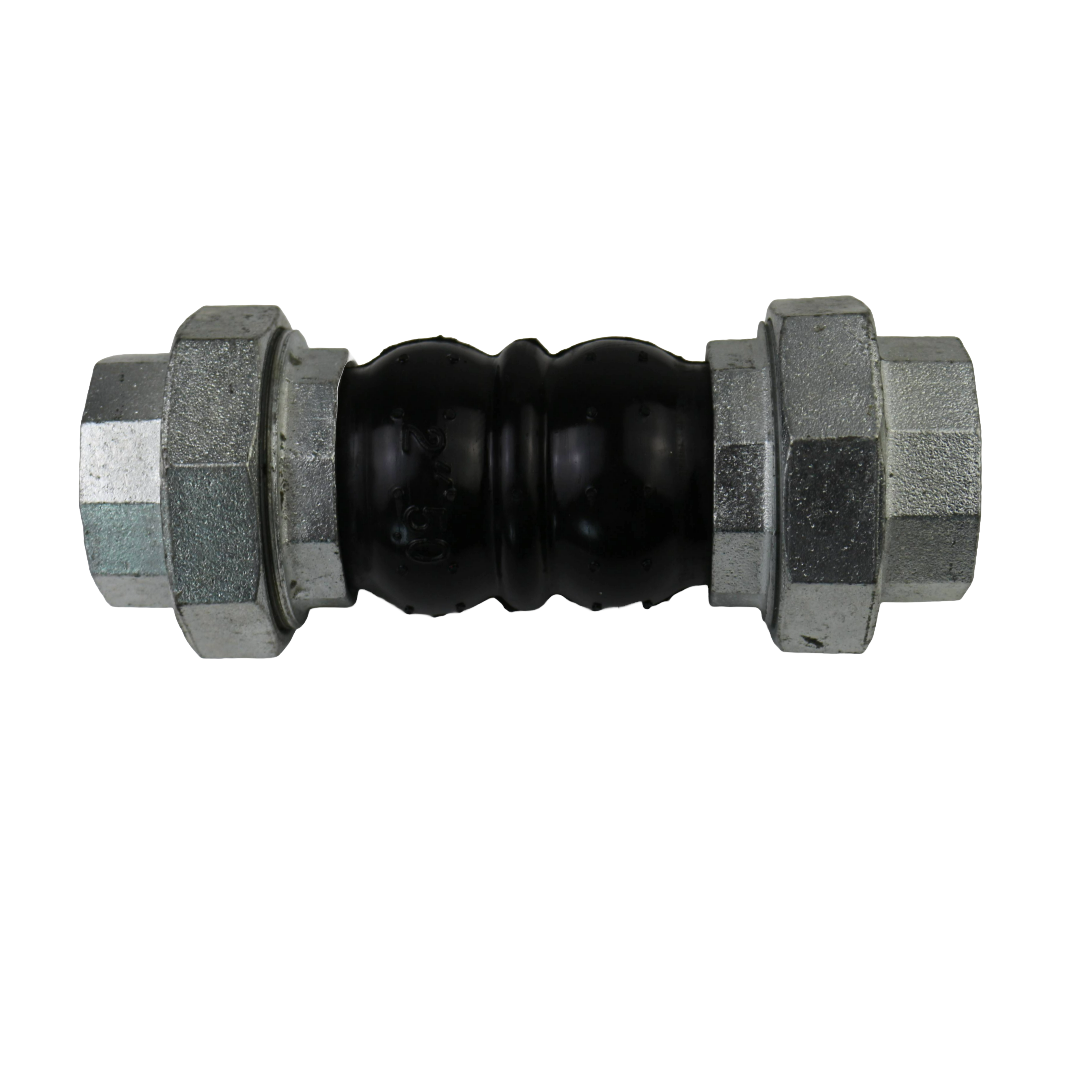

Union Rubber Expansion Joint

The Threaded Rubber Expansion Joint, also called screw-type rubber joint, threaded flexible connector, or threaded rubber bellow, is designed for small-diameter pipeline systems requiring flexible vibration isolation. It connects to pipelines via male or female threads, making installation fast and leak-proof. Commonly used in HVAC, water circulation systems, and pump outlets, it absorbs vibrations, compensates slight misalignments, and extends system lifespan.

Key Features

Technical Specifications

| Nominal Diameter (DN) | Inch | Length (L) mm | Axial Extension mm | Lateral Displacement mm | Angular Deflection (°) |

|---|

| DN20 | ¾” | 110 | 5 | 6 | 15 |

| DN25 | 1″ | 115 | 5 | 6 | 15 |

| DN32 | 1¼” | 120 | 6 | 6 | 15 |

| DN40 | 1½” | 125 | 6 | 6 | 15 |

| DN50 | 2″ | 130 | 7 | 7 | 15 |

| DN65 | 2½” | 140 | 7 | 7 | 15 |

| DN80 | 3″ | 160 | 8 | 8 | 15 |

| Project | Unit | TRJ-1 | TRJ-2 | TRJ-3 |

|---|

| Model | – | TRJ-1 | TRJ-2 | TRJ-3 |

| Working Pressure | MPa (kgf/cm²) | 1.0 (10) | 1.6 (16) | 2.5 (25) |

| Burst Pressure | MPa (kgf/cm²) | 2.0 (20) | 3.0 (30) | 4.5 (45) |

| Vacuum Resistance | KPa (mmHg) | 53.3 (400) | 86.7 (650) | 100 (750) |

| Operating Temperature | °C | -15 ~ 115°C (Special: -30 ~ 250°C) | -15 ~ 115°C (Special: -30 ~ 250°C) | -15 ~ 115°C (Special: -30 ~ 250°C) |

| Applicable Media | – | Air, Compressed Air, Water, Seawater, Hot Water, Oil, Acid, Alkali, etc. | Air, Compressed Air, Water, Seawater, Hot Water, Oil, Acid, Alkali, etc. | Air, Compressed Air, Water, Seawater, Hot Water, Oil, Acid, Alkali, etc. |

| Material | Temperature Range (°C) | Oil Resistance | Acid & Alkali Resistance | Elasticity | Abrasion Resistance | Typical Applications |

|---|

| EPDM | -40 ~ 120 | Poor | Excellent | Excellent | Medium | Water, Steam, Air |

| NR (Natural Rubber) | -30 ~ 80 | Poor | Medium | Excellent | Excellent | Industrial Water, Air |

| NBR | -20 ~ 100 | Excellent | Medium | Good | Good | Oil, Lubrication Systems |

| Neoprene | -35 ~ 100 | Good | Good | Medium | Good | Seawater, Mild Chemicals |

| Silicone | -60 ~ 200 | Poor | Poor | Good | Low | Food Grade, Medical |

| FKM (Viton) | -20 ~ 250 | Excellent | Excellent | Medium | Excellent | Chemical, High Temp Oil |

| Butyl (IIR) | -40 ~ 120 | Poor | Good | Excellent | Medium | Gas, Acidic Gases |

Preparation:

Ensure the threaded ends of the joint and connecting pipes are clean and free of damage. Apply appropriate sealing tape or sealant.Connection:

Hand-tighten the rubber joint onto the pipeline, ensuring threads engage properly without cross-threading.Tightening:

Gradually tighten with a wrench to achieve a secure and leak-free connection, but avoid over-tightening to prevent damage to the joint.Inspection:

Check alignment and tightness after installation. Perform a pressure test to confirm no leakage is present.

Regular Checks:

Inspect regularly for any sign of leakage, deformation, cracks, or corrosion on threads and rubber body.Thread Condition:

Periodically check thread conditions. Reapply sealant or sealing tape if leakage occurs.Replacement:

Replace immediately upon visible damage, excessive wear, or if the joint has exceeded its service life.Protection:

Avoid direct exposure to harmful chemicals, oils, and extreme temperatures to extend the life of the rubber joint.Cleaning:

Regularly clean threads and rubber surfaces gently using mild detergent and water to prevent corrosion and deterioration.

What kind of documents are included with the shipment?

We provide a full set of export documents, including packing list, commercial invoice, product test report, and material certificate. Custom clearance documents are also available upon request.

What sizes and materials are available for rubber expansion joints?

Our rubber joints are available in sizes from DN32 to DN1200, and materials include EPDM, NBR, Neoprene, PTFE-lined rubber, and food-grade silicone. Custom materials are available for specific industries.

Can you produce customized rubber joints according to our drawing?

Yes. We support OEM and ODM services. Just send us your drawing or specifications, and our technical team will provide a matching solution with fast production.

Why Choose Zhengda Valve & Pipeline Co., Ltd.?

Let Us Help With Your Pipeline Needs

Contact Us Now

Let Us Help With Your Pipeline Needs

We respond quickly to inquiries and provide expert support on rubber joints, metal hoses, and customized solutions.