Zhengda Valve

One-Stop Supplier for Rubber Joints, Bellows, and Waterproof Casings

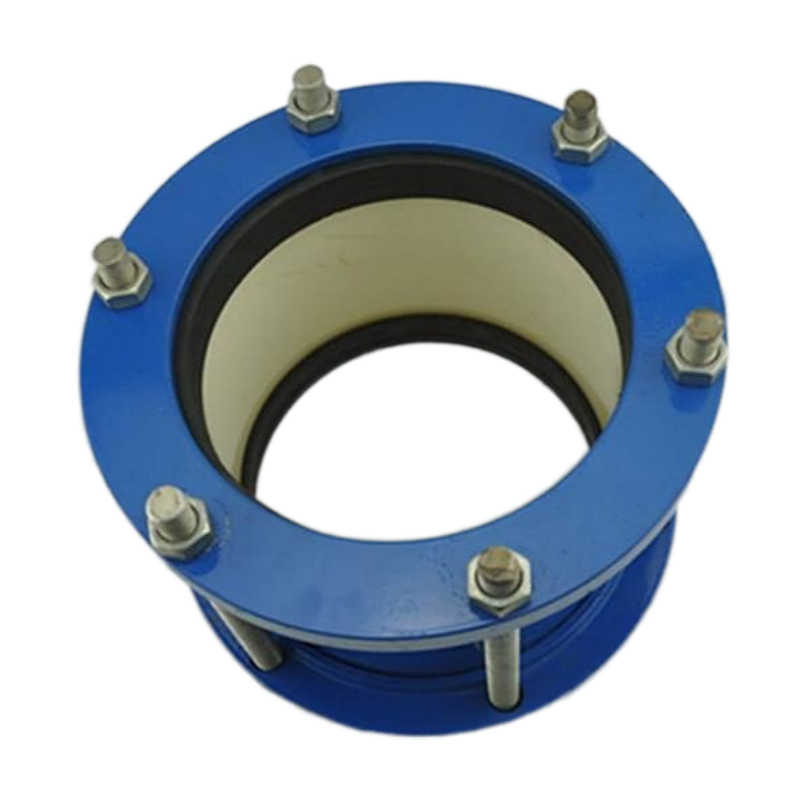

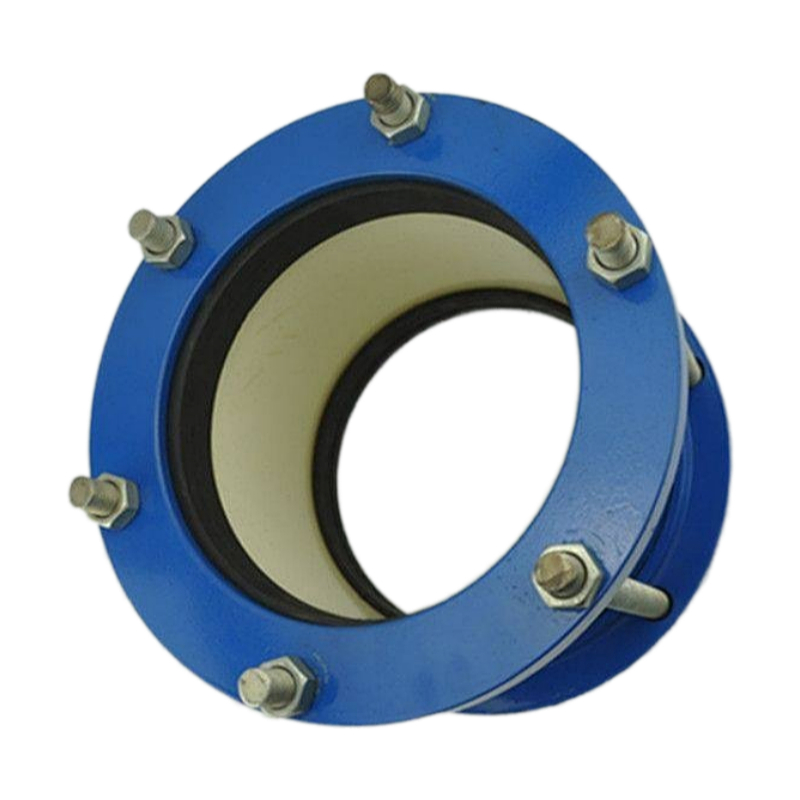

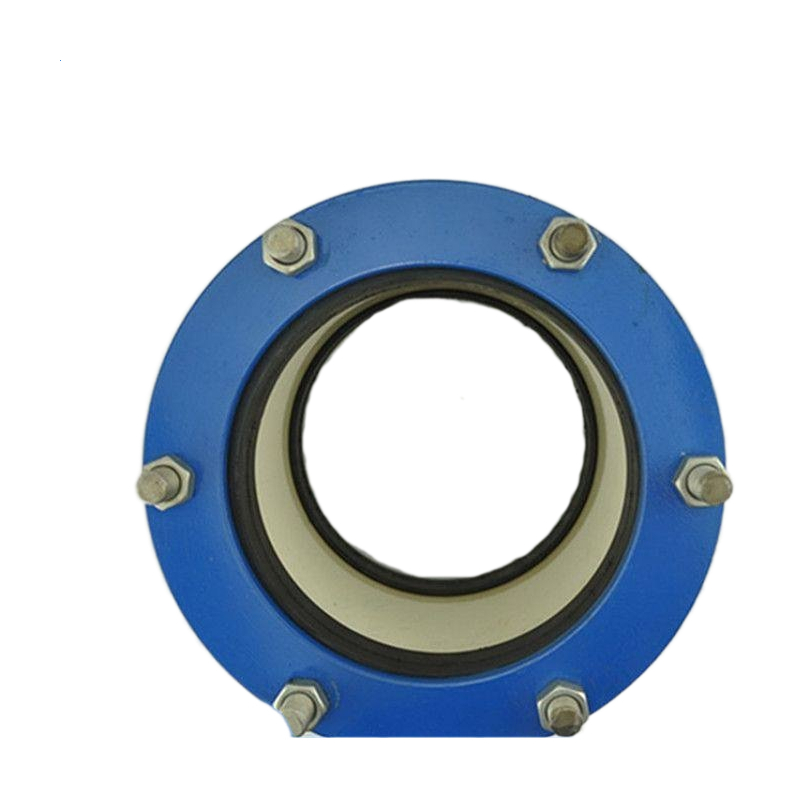

Gland Type Dismantling Joint

Gland Type Dismantling Joint is a flanged loose sleeve coupling designed for flexible and reliable pipe connections in water supply, HVAC, drainage, and industrial pipeline systems. It allows axial adjustment and easy disassembly of valves, pumps, and other components without disturbing the surrounding piping.

This joint features a gland compression structure that provides excellent sealing performance and compensation for axial displacement. Its detachable design makes installation and maintenance more efficient, especially in tight or limited spaces.

Made of ductile iron or carbon steel body with anti-corrosion coating, and equipped with rubber sealing gaskets (usually EPDM or NBR), the gland dismantling joint ensures long service life under high pressure and temperature conditions.

Whether used in municipal pipelines, power plants, or wastewater treatment systems, this joint provides a cost-effective and secure connection solution for flanged piping systems.

Key Features

Technical Specifications

📐 Gland Type Dismantling Joint – Dimensions & Sizes

| Nominal Diameter (DN) | Inch | Total Length (L) mm | Flange Thickness (b) mm | Bolt Qty (pcs) | Bolt Hole Dia. (mm) | Bolt Circle Dia. (D1) mm | Axial Adjustment Range (mm) |

|---|---|---|---|---|---|---|---|

| DN50 | 2″ | 180 | 18 | 4 | 18 | 125 | 10 |

| DN65 | 2.5″ | 190 | 20 | 4 | 18 | 145 | 10 |

| DN80 | 3″ | 200 | 22 | 8 | 18 | 160 | 12 |

| DN100 | 4″ | 210 | 24 | 8 | 18 | 180 | 12 |

| DN125 | 5″ | 230 | 26 | 8 | 18 | 210 | 14 |

| DN150 | 6″ | 250 | 28 | 8 | 18 | 240 | 14 |

| DN200 | 8″ | 270 | 30 | 12 | 18 | 295 | 16 |

| DN250 | 10″ | 290 | 32 | 12 | 18 | 350 | 16 |

| DN300 | 12″ | 310 | 34 | 12 | 18 | 400 | 18 |

| DN350 | 14″ | 340 | 36 | 16 | 18 | 460 | 18 |

| DN400 | 16″ | 360 | 38 | 16 | 18 | 515 | 18 |

| DN450 | 18″ | 380 | 40 | 20 | 18 | 565 | 20 |

| DN500 | 20″ | 400 | 42 | 20 | 18 | 620 | 20 |

| DN600 | 24″ | 440 | 48 | 20 | 18 | 725 | 20 |

🔧 Gland Type Dismantling Joint – Technical Parameters

| Parameter | Unit | Specification |

|---|---|---|

| Product Name | – | Gland Type Dismantling Joint (Gland Loose Sleeve Coupling) |

| Model Code | – | ZD-GDJ (Gland Dismantling Joint) |

| Nominal Diameter Range | mm | DN50 – DN600 |

| Connection Type | – | Double Flange with Gland Compression Structure |

| Working Pressure Levels | MPa / Bar | PN10 (1.0 MPa), PN16 (1.6 MPa), PN25 (2.5 MPa) |

| Shell Pressure Test | MPa | 1.5 × Working Pressure |

| Sealing Pressure Test | MPa | 1.1 × Working Pressure |

| Axial Adjustment Range | mm | 10 – 20 mm (varies by DN size) |

| Angular Deflection | ° | ≤ 8° |

| Lateral Displacement | mm | Up to 20 mm |

| Sealing Performance | – | Zero visible leakage under rated pressure |

| Applicable Temperature | °C | -20°C ~ +200°C (depending on gasket material) |

| Medium Compatibility | – | Potable Water, Wastewater, Oil, Gas, Compressed Air, Weak Acid/Base |

| Installation Environment | – | Above-ground and Indoor preferred (Underground use requires special treatment) |

| Flange Standard Options | – | GB/T 9115, EN 1092, ANSI B16.5, ISO 7005 (Customizable) |

| Design Life Expectancy | Years | 8 – 15 Years (with proper installation and periodic maintenance) |

📌 Feature Summary:

No welding required – ideal for retrofit or limited-space installations

Split gland compression – provides flexible sealing and adjustable axial length

Quick disassembly – convenient for pump/valve maintenance or replacement

🧱 Gland Type Dismantling Joint – Materials Specification

| Component | Material Option 1 | Material Option 2 | Application Notes |

|---|---|---|---|

| Main Body | Ductile Iron (GGG40 / GGG50) | Carbon Steel (Q235 / Q345) | GGG50: Standard for water supply & drainage; Q345: For industrial strength requirements |

| Flanges | Carbon Steel (Q235B / Q345B) | Stainless Steel (SS304 / SS316) | Drilled per GB, ANSI, EN, or DIN flange standard |

| Compression Gland Ring | Cast Iron / Ductile Iron | Stainless Steel | Used to clamp and compress the sealing area |

| Inner Sleeve | Carbon Steel | Stainless Steel / Coated Steel | Telescopic section, in contact with media or pipe ends |

| Sealing Gasket | EPDM (Ethylene Propylene Rubber) | NBR / PTFE | EPDM: Water, air; NBR: Oil/fuel; PTFE: Chemicals or high-temperature applications |

| Bolts & Nuts | Carbon Steel, Zinc Plated | Stainless Steel A2-70 / A4-80 | Galvanized or stainless depending on environment |

| Coating (Internal & External) | Fusion Bonded Epoxy (≥250μm) | Bitumen Paint / Bare SS | FBE is standard; bitumen for buried use; stainless can remain uncoated if polished |

| Surface Finish | Shot-blasted to Sa2.5 | Polished & Passivated (for SS only) | Improves coating adhesion; passivation resists chemical attack |

🔍 Material Selection Notes:

Ductile iron + epoxy is ideal for civil and municipal pipelines.

Stainless steel (SS316) is recommended for marine, food-grade, or chemical industries.

PTFE gasket is the best choice for aggressive chemicals or temperatures > 120°C.

Fusion Bonded Epoxy (FBE) protects both potable water and industrial systems for up to 15–20 years when undamaged.

🛠️ Gland Type Dismantling Joint – Installation Guide

| Step | Installation Task | Detailed Procedure & Instructions |

|---|---|---|

| 1️⃣ | Pre-Installation Inspection | – Check product for damage, cracks, corrosion, or missing components – Verify that all bolts, gaskets, and gland rings are present |

| 2️⃣ | Pipeline Preparation | – Pipe ends should be clean, flat, and burr-free – Ensure pipeline is aligned and flanges are parallel |

| 3️⃣ | Gasket Selection & Placement | – Choose the correct gasket type (EPDM/NBR/PTFE) based on media – Insert gasket between flange and joint face |

| 4️⃣ | Positioning the Joint | – Slide the joint sleeve into one pipe end – Adjust axial position so that both flanges align and gasket contact is correct |

| 5️⃣ | Bolt Insertion & Hand-Tightening | – Insert flange bolts and loosely tighten in a cross-pattern – Do not fully compress gasket at this stage |

| 6️⃣ | Gland Compression Assembly | – Tighten gland compression bolts evenly in sequence (e.g. top-bottom-left-right) – Gland compresses gasket to create a seal |

| 7️⃣ | Torque Tightening (Final) | – Use torque wrench to apply final torque (based on DN and bolt size) – Avoid over-tightening which may deform the gasket |

| 8️⃣ | Axial Adjustment (if needed) | – Slightly retract or extend the sleeve before fully tightening to accommodate pipeline movement allowance |

| 9️⃣ | Sealing Verification | – Check for even gasket compression around the entire joint – Ensure no visible extrusion of the gasket |

| 🔟 | Pressure Test | – Conduct hydrostatic pressure test at 1.5× working pressure – Check for leaks at flange and compression seal |

| ✅ | Commissioning | – Once leak-free, commission pipeline system – Record torque values and date for future maintenance reference |

⚠️ Important Notes

| Item | Best Practice |

|---|---|

| Gasket Installation | Always center the gasket; avoid folds or displacement |

| Bolt Tightening Pattern | Always tighten in a cross/star pattern to ensure even pressure |

| Pipeline Support | Joint should not bear pipe weight – install pipe supports on both ends |

| Underground Use | Use bitumen wrap or additional protective sleeves for buried installations |

| Axial Movement Function | Leave slight room for expansion/contraction if used as flexible coupling |

🧰 Gland Type Dismantling Joint – Maintenance Guide

| Maintenance Task | Recommended Frequency | Procedure & Instructions | Purpose / Result |

|---|---|---|---|

| 🔍 Visual Inspection | Monthly / Quarterly | – Inspect outer surfaces for rust, peeling coating, or visible damage – Check for gasket extrusion or flange leakage | Early detection of deterioration and safety assurance |

| 🔧 Compression Bolt Retightening | Every 6 months | – Use torque wrench to recheck and retighten gland bolts – Follow original cross-sequence pattern | Prevent leakage due to vibration, relaxation, or gasket compression loss |

| 🧪 Seal Integrity & Gasket Check | Every 6–12 months | – Inspect compression gasket condition: cracks, hardening, or flattening – Replace if any abnormal wear is found | Maintain effective sealing and prevent sudden failure |

| 🧱 Sleeve Movement Verification | Annually | – Ensure sleeve is not seized due to rust or over-tightening – Confirm axial adjustability if used for expansion | Retains joint flexibility and thermal compensation function |

| 🎨 Surface Coating Maintenance | Annually / As needed | – Clean the joint surface and reapply FBE or anti-corrosive coating – For buried joints, check wrapping condition | Protects steel structure and extends service life |

| 🔩 Fastener Replacement | Every 3–5 years | – Replace flange bolts and nuts if they show signs of corrosion or thread damage – Use same material grade or equivalent | Ensure reliable flange connection and mechanical integrity |

| 🧾 Maintenance Record Keeping | After every service | – Record date, torque values, replaced parts, and inspector name – Attach photos if abnormality is found | Supports long-term traceability and warranty-related technical verification |

⚠️ Common Failure Scenarios & Solutions

| Symptom | Likely Cause | Recommended Action |

|---|---|---|

| Gasket leakage | Gasket aged, loose bolts, or poor installation | Replace gasket; retorque compression bolts evenly |

| Gasket extrusion | Overcompression or oversized axial movement | Replace gasket with correct size; recheck bolt torque and pipe fit |

| Bolt thread corrosion | Humid environment or coating failure | Replace bolts and repaint or galvanize contact areas |

| Sleeve jamming / no axial movement | Rust accumulation or overtight installation | Clean and re-grease sleeve area; disassemble if necessary |

✅ Recommended Spare Parts

Compression Gaskets (EPDM / NBR / PTFE – based on working media)

Full Bolt & Nut Kits (galvanized carbon steel or stainless steel)

Anti-corrosion Coating (FBE patch kits or bituminous paint)

❓ What is a Gland Type Loose Sleeve Coupling used for?

This type of coupling is designed to absorb axial displacement and compensate for misalignment in pipeline systems. It is widely used in water supply, sewage treatment, HVAC, and fire protection systems where flexible and reliable pipe connections are required.

❓ What materials are available for gland-type couplings?

Our couplings are available in carbon steel, ductile iron, or stainless steel bodies, with EPDM or NBR rubber gaskets. All metal parts can be treated with anti-corrosion coatings such as epoxy or hot-dip galvanizing.

❓ Can I request customized sizes or designs?

Yes, Zhengzhou Hongze Valve & Pipeline Equipment Co., Ltd. supports OEM and ODM customization. Just send us your drawings or installation requirements, and our technical team will provide tailored solutions.

❓ What makes your gland-type couplings reliable?

We use high-quality raw materials, implement strict quality control, and test each coupling before shipment. The gland structure ensures tight sealing under pressure, and the bolts are reinforced to prevent loosening during long-term operation.

Let Us Help With Your Pipeline Needs

Contact Us Now

Let Us Help With Your Pipeline Needs

We respond quickly to inquiries and provide expert support on rubber joints, metal hoses, and customized solutions.