Zhengda Valve

One-Stop Supplier for Rubber Joints, Bellows, and Waterproof Casings

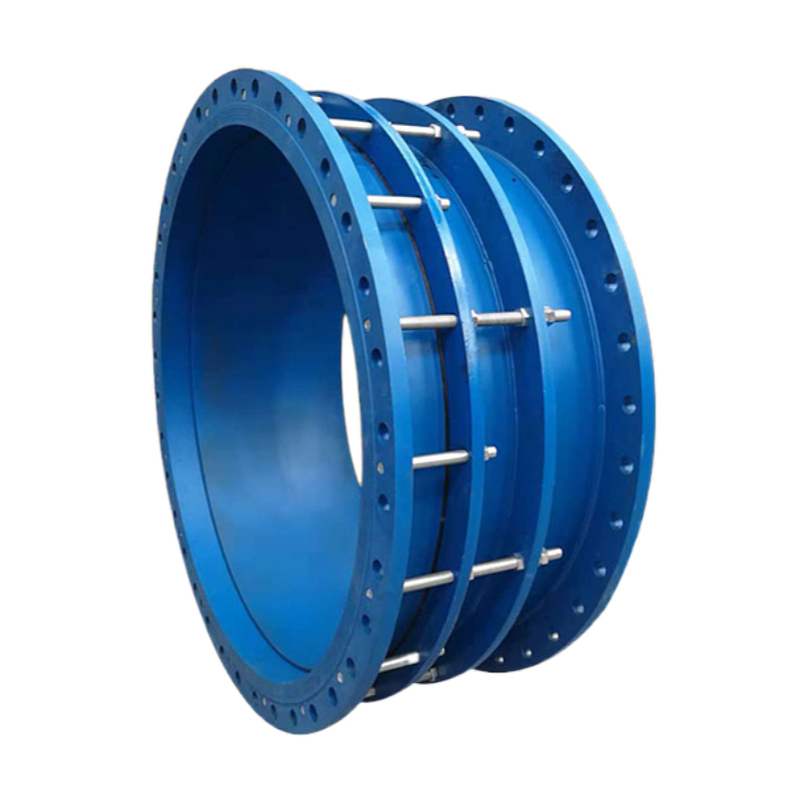

Double Flange Dismantling Joint

Key Features

Technical Specifications

📐 Double-Flange Transmission Joint – Dimensions & Sizes

| Nominal Diameter (DN) | Inch | Length (L) mm | Flange Thickness (b) mm | Bolt Qty (n) | Bolt Hole Dia. (mm) | Bolt Circle Dia. (D1) mm | Axial Extension (mm) | Lateral Displacement (mm) | Angular Deflection (°) |

|---|---|---|---|---|---|---|---|---|---|

| DN50 | 2″ | 230 | 18 | 4 | 18 | 125 | 10 | 10 | 10 |

| DN65 | 2.5″ | 250 | 20 | 4 | 18 | 145 | 10 | 12 | 10 |

| DN80 | 3″ | 270 | 22 | 8 | 18 | 160 | 12 | 14 | 10 |

| DN100 | 4″ | 290 | 24 | 8 | 18 | 180 | 12 | 14 | 10 |

| DN125 | 5″ | 310 | 26 | 8 | 18 | 210 | 14 | 15 | 9 |

| DN150 | 6″ | 330 | 28 | 8 | 18 | 240 | 14 | 15 | 9 |

| DN200 | 8″ | 350 | 30 | 12 | 18 | 295 | 16 | 16 | 9 |

| DN250 | 10″ | 380 | 32 | 12 | 18 | 350 | 16 | 16 | 9 |

| DN300 | 12″ | 400 | 34 | 12 | 18 | 400 | 18 | 18 | 8 |

| DN350 | 14″ | 420 | 36 | 16 | 18 | 460 | 18 | 18 | 8 |

| DN400 | 16″ | 440 | 38 | 16 | 18 | 515 | 18 | 20 | 8 |

| DN450 | 18″ | 460 | 40 | 20 | 18 | 565 | 20 | 20 | 7 |

| DN500 | 20″ | 480 | 42 | 20 | 18 | 620 | 20 | 20 | 7 |

| DN600 | 24″ | 520 | 48 | 20 | 18 | 725 | 20 | 20 | 7 |

| DN700 | 28″ | 560 | 52 | 24 | 18 | 840 | 20 | 20 | 6 |

| DN800 | 32″ | 600 | 56 | 24 | 18 | 950 | 20 |

🔧 Double-Flange Transmission Joint – Technical Parameters

| Parameter | Unit | Specification |

|---|---|---|

| Product Model | – | ZD-DFJ (Double-Flange Transmission Joint) |

| Nominal Diameter Range | mm | DN50 – DN800 |

| Working Pressure Levels | MPa / Bar | PN10 (1.0 MPa), PN16 (1.6 MPa), PN25 (2.5 MPa) (customizable) |

| Shell Test Pressure | MPa | 1.5 × working pressure |

| Seal Test Pressure | MPa | 1.1 × working pressure |

| Temperature Resistance Range | °C | -20°C to +200°C (depending on gasket and coating selection) |

| Medium Compatibility | – | Water, Wastewater, Oil, Compressed Air, Weak Acids & Alkalis, Industrial Fluids |

| Axial Compensation (max) | mm | ±10 ~ ±20 (depending on DN size) |

| Lateral Displacement (max) | mm | 10 ~ 20 (depending on DN size) |

| Angular Deflection (max) | Degrees (°) | 6° – 10° (varies by diameter) |

| Connection Type | – | Double flange connection, drilled per GB/ANSI/DIN/EN standards |

| Standard Compliance | – | GB/T 12465, CJ/T 156, ISO 7005, ANSI B16.5, EN 1092 |

| Anti-Corrosion Coating | – | Fusion Bonded Epoxy ≥ 250μm (standard), Hot-Dip Galvanized, or SS surface finish |

| Installation Environment | – | Aboveground, Underground, Indoor/Outdoor, Buried Pipelines |

| Service Life (Recommended) | Years | 8 – 15 Years (depending on medium and maintenance conditions) |

🧱 Double-Flange Transmission Joint – Materials Specification

| Component | Material Option 1 | Material Option 2 | Application Notes |

|---|---|---|---|

| Main Body | Ductile Iron (GGG40 / GGG50) | Carbon Steel (Q235 / Q345) | GGG: Standard for water systems; Q345: Ideal for higher strength or industrial use |

| Stainless Steel (SS304 / SS316) | – | SS316 preferred for highly corrosive or marine environments | |

| Dual Flanges | Carbon Steel (Q235 / Q345) | Stainless Steel (SS304 / SS316) | Flange holes drilled per standard (GB, ANSI, DIN, EN); SS recommended for chemical use |

| Gaskets (Seals) | EPDM (Ethylene Propylene Rubber) | NBR (Nitrile Rubber), PTFE | EPDM: Water, steam, alkali; NBR: Oil & fuel; PTFE: High-temp or corrosive media |

| Bolts / Nuts | Carbon Steel, Zinc-Plated | Stainless Steel (SS304 / SS316) | SS preferred in corrosion-prone, humid, or coastal regions |

| Tie Rods (if limited) | Carbon Steel with Hot-Dip Galvanization | Stainless Steel | Used for thrust resistance; prevent over-extension under internal pressure |

| Coating (Exterior & Interior) | Fusion Bonded Epoxy (≥250 μm) | Bitumen / Asphalt Paint | FBE: Industrial standard anti-corrosion coating; Asphalt: Used for buried pipelines |

| Surface Finish (for SS options) | Polished / Passivated | – | Polishing reduces pitting; passivation improves resistance to chemicals |

💡 Material Selection Notes:

Ductile Iron is cost-effective and meets most water and civil application standards.

Carbon Steel offers high strength and can be paired with anti-rust coatings.

Stainless Steel is preferred for long-term durability and harsh chemical environments.

PTFE Gaskets should be used when operating temperature exceeds 120°C or for strong acid/alkali media.

🛠️ Double-Flange Transmission Joint – Installation Guide

| Step | Procedure | Details & Notes |

|---|---|---|

| 1️⃣ | Preparation Before Installation | – Inspect all components for damage, rust, or debris – Verify the joint size, pressure rating, and flange standard match pipeline requirements |

| 2️⃣ | Pipeline Alignment | – Ensure pipeline ends are aligned and concentric – Misalignment must be corrected before installing the joint |

| 3️⃣ | Flange Surface Cleaning | – Remove dust, oil, and rust from the flange faces – Ensure flatness and smoothness of sealing surfaces |

| 4️⃣ | Gasket Placement | – Position the gasket (EPDM/NBR/PTFE) evenly between flanges – Gasket must match pressure and medium type |

| 5️⃣ | Insert and Tighten Bolts | – Insert bolts symmetrically into flange holes – Tighten bolts gradually in a cross/star pattern to ensure even pressure |

| 6️⃣ | Torque Application | – Use torque wrench to apply recommended torque based on DN and pressure – Avoid over-tightening to prevent gasket deformation |

| 7️⃣ | Axial Adjustment (if required) | – Pre-adjust allowable axial movement before final bolt tightening (if applicable) – Lock limit rods after adjustment (for limit models) |

| 8️⃣ | Final Check & Positioning | – Ensure flange faces are parallel – Verify all bolts are uniformly tightened and gasket is not exposed |

| 9️⃣ | Pressure Testing | – Conduct hydrostatic or pneumatic pressure testing – Observe for leakage at flanges and tighten if necessary |

| 🔟 | Commissioning & Record Keeping | – If leak-free, proceed to commission the system – Record installation date, torque values, and material batch for future maintenance reference |

⚠️ Important Notes:

Do not use the joint to forcibly correct pipe misalignment.

Do not weld or modify any part of the joint post-installation.

Support the pipeline independently; the joint should not bear the pipe weight.

For buried use, apply additional waterproof wrapping or asphalt protection.

🧰 Double-Flange Transmission Joint – Maintenance Guide

| Maintenance Task | Frequency | Procedure | Purpose / Notes |

|---|---|---|---|

| 🔎 Visual Inspection | Monthly / Quarterly | – Check for signs of external leakage – Inspect paint or coating condition – Look for flange deformation or bolt corrosion | Early detection of damage or potential failure |

| 🔧 Bolt Retightening | Every 3–6 months | – Use torque wrench to check and retighten bolts – Follow original cross-tightening sequence | Prevents bolt loosening due to vibration or thermal cycling |

| 🧪 Seal Integrity Check | Every 6 months | – Inspect gasket sealing area for hardening, cracks, or leaks – Replace gasket if degradation is detected | Ensures reliable sealing performance over time |

| 🧹 Surface Cleaning | Every 6–12 months | – Remove surface dust, dirt, or chemical residues – Repaint exposed surfaces if epoxy coating is damaged | Prolongs the lifespan of the joint |

| 🧱 Coating Inspection | Annually | – Examine anti-corrosion coating or galvanization – Touch-up or re-coat as necessary | Prevents long-term corrosion damage |

| 🔩 Fastener Replacement | Every 2–3 years | – Replace bolts/nuts if showing visible rust or thread wear – Always use matching material and grade | Ensures mechanical strength and safety |

| 🔁 Joint Replacement Check | After 5–8 years in use | – Review operational logs for pressure/temperature conditions – Check for permanent deformation or performance drop | Helps determine if a full replacement is needed |

| 🧾 Record & Documentation | During every maintenance | – Log all inspection results, tightening values, replacements – Store with project or system documentation | Establishes maintenance history for compliance and auditing |

⚠️ Failure Indicators – Immediate Action Required:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Persistent leakage | Aged or deformed gasket | Replace gasket immediately |

| Corroded bolts/nuts | Environmental moisture or chemical exposure | Replace all affected fasteners |

| Surface coating peeling or flaking | UV, acid, or underground water erosion | Clean and recoat surface with industrial epoxy |

| Gasket extrusion / visible swelling | Overpressure or incompatible media | Replace gasket and verify working conditions |

🔍 What is a Double Flange Dismantling Joint used for?

A Double Flange Dismantling Joint is used to simplify the installation and removal of valves, pumps, and other piping components. It provides axial flexibility and allows quick disassembly without disturbing the pipeline system.

🔧 What sizes and pressure ratings are available?

Standard sizes range from DN65 to DN2000, with pressure ratings from PN10 to PN25. Custom sizes, drilling standards (DIN, ANSI, BS, JIS), and flange types are available upon request to suit project requirements.

🏗️ Can it be customized for specific installation requirements?

Yes. We provide custom face-to-face lengths, flange standards, coating options, and even materials (carbon steel, ductile iron, stainless steel) to match your system design or retrofit needs.

🛡️ What are the advantages of using this joint?

Double flange dismantling joints offer easy alignment, secure sealing, and quick maintenance access, reducing installation labor and downtime. They are ideal for municipal water, wastewater, and industrial pipelines.

Let Us Help With Your Pipeline Needs

Contact Us Now

Let Us Help With Your Pipeline Needs

We respond quickly to inquiries and provide expert support on rubber joints, metal hoses, and customized solutions.